- Founded in 1966

We are building the future of engineering

MES stands at the forefront of engineering, continuously developing innovative solutions that redefine industry standards. Our team of experts is dedicated to creating products that not only meet but exceed expectations.

10k+ PROJECTS

For decades, we have completed more than 10,000 projects, showcasing our expertise and commitment to excellence. Our solutions span multiple industries, ensuring high-quality outcomes in automotive, alternative energy, and beyond. Each project reflects our dedication to innovation and precision.

100% satification

Customer satisfaction is our top priority. With a proven track record of 100% satisfaction, we consistently deliver reliable and innovative solutions. Our attention to detail and unwavering commitment to quality ensure that every client receives exceptional service and results tailored to their specific needs.

- People

Our Legacy

For over 50 years, Middleville Engineered Solutions (MES) has been exceeding our customers’ needs in a wide range of industries. From its humble beginnings in 1966, to today, being located in a 120,000 square foot state-of-the-art facility, Middleville Engineered Solutions has evolved into a world class engineered products organization.

- Engineered Solutions

- Company

Customer empowerment in a future-focused world

Middleville Engineered Solutions has developed a reputation for proactively partnering with our customers to develop innovative solutions to the industries most complex problems. MES’s team of product engineers work side by side with our customers to find new ways to improve performance, reduce weight, improve quality, and reduce cost on new and existing products.

Serving as an extension of our customers engineering team, MES has developed a unique process for developing and implementing solutions not commonly found in the metal stamping industry. Our closed loop development process allows us to take a part from concept to production in less time and at a lesser cost than our competition.

MES’s in-house prototype and R&D facility is uniquely positioned to compliment our product development and tooling capabilities. Our ability to develop and validate our product designs in-house allows us to meet the industry’s most aggressive development schedules.

All prototype processes are developed with hard tool intent, allowing MES to validate the proposed mass production tooling process early in the development cycle. Further, we are able to provide our customers with mass production representative parts for product validation (PV) and design validation (DV) testing, resulting in reduced risk of product and process failure later in the development cycle.

MES specializes in the simulation, design, and build of progressive dies, line dies and transfer dies for our in-house production needs as well as for our contract tooling customers.

Utilizing our in-house FEA software (PamStamp) MES is capable of full product and process simulations. Tooling designs are completed by our seasoned tooling design engineers using SolidWorks software.

MES’s structured design review process solicits input from a cross functional team of designers, tool makers, engineers, manufacturing and quality experts to ensure that the proposed process will meet or exceed the most stringent requirements.

All prototype processes are developed with hard tool intent, allowing MES to validate the proposed mass production tooling process early in the development cycle. Further, we are able to provide our customers with mass production representative parts for product validation (PV) and design validation (DV) testing, resulting in reduced risk of product and process failure later in the development cycle.

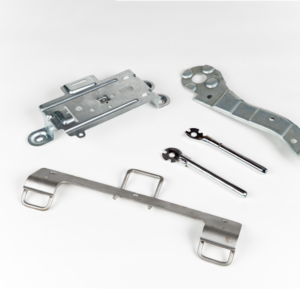

Middleville Engineered Solutions’ manufacturing capabilities include progressive & transfer press stamping (60 to 1100 ton), manual & robotic welding (resistance, MIG, TIG, Plasma, Laser), tapping, riveting, automated & hand assembly.

MES is IATF:16949 certified and has a state of the art quality lab. Our commitment to LEAN principals has allowed us to continually find new ways to drive waste out of our manufacturing processes.

Producing parts from low carbon steel, AHSS, UHSS, aluminum and stainless steel in gages ranging from .020” to .314” (0.5mm – 8mm) MES has the requisite experience to support the needs of our customers no matter what industry they serve.

Middleville Engineered Solutions’ manufacturing capabilities include manual & robotic welding (resistance, MIG, TIG, Plasma, Laser), tapping, riveting, automated & hand assembly.

MES is IATF:16949 certified and has a state of the art quality lab. Our commitment to LEAN principals has allowed us to continually find new ways to drive waste out of our manufacturing processes.

Producing parts from low carbon steel, AHSS, UHSS, aluminum and stainless steel in gages ranging from .020” to .314” (0.5mm – 8mm) MES has the requisite experience to support the needs of our customers no matter what industry they serve.

Middleville Engineered solutions excels in precision die details, ensuring exact specifications using any 3d design. We offer die-ready details for new construction, engineering changes, and maintenance. Our reverse engineering capability guarantees accurate replacements, enhancing capacity and efficiency.

- Case Studies

Sustainable for a stronger tomorrow

AUTOMOTIVE SHIFT TUBE

One of our standout achievements is the transformation of a traditionally cast automotive shift tube into a high-quality stamped part using our proprietary Wrapped Tubular Stamping Technology.

TUBE AND BRACKET COMBINATION

Our work with a leading office furniture manufacturer to redesign a crucial component of their cubicle wall system showcases our commitment to excellence and our capability to provide significant value to our customers.

AUTOMOTIVE HEADREST TUBE

One such innovation was the redesign of an automotive headrest tube, traditionally produced through a multi-step welding process.

- Careers

Pioneering a New Era of MANFACURING Excellence

Our relentless pursuit of excellence and innovation has established MES as a leader in the industry. We are committed to maintaining this legacy by continuously investing in new technologies and sustainable practices.

INVESTING TODAY FOR A SUSTAINABLE TOMORROW

Events

Unlocking value through events: building relationships, sharing insights, and maximizing opportunities.

Our People

Meet the dedicated people behind MES. Our people drive innovation and excellence. Watch their stories and get inspired.

- Company