Commitment to Quality and Sustainability

Middleville Engineered Solutions (MES) is at the forefront of innovation in the automotive industry, providing cutting-edge solutions that enhance vehicle performance, safety, and efficiency. Our expertise in metal forming, welding, and assembly allows us to deliver high-quality components that meet the rigorous demands of the automotive sector.

We specialize in a wide range of automotive solutions, including:

- Stamping: Our advanced stamping capabilities include progressive and transfer press stamping, enabling us to produce complex parts with precision and efficiency.

- Welding: We offer both manual and robotic welding solutions, including MIG, TIG, Plasma, and Laser welding, ensuring strong and reliable joints for automotive components.

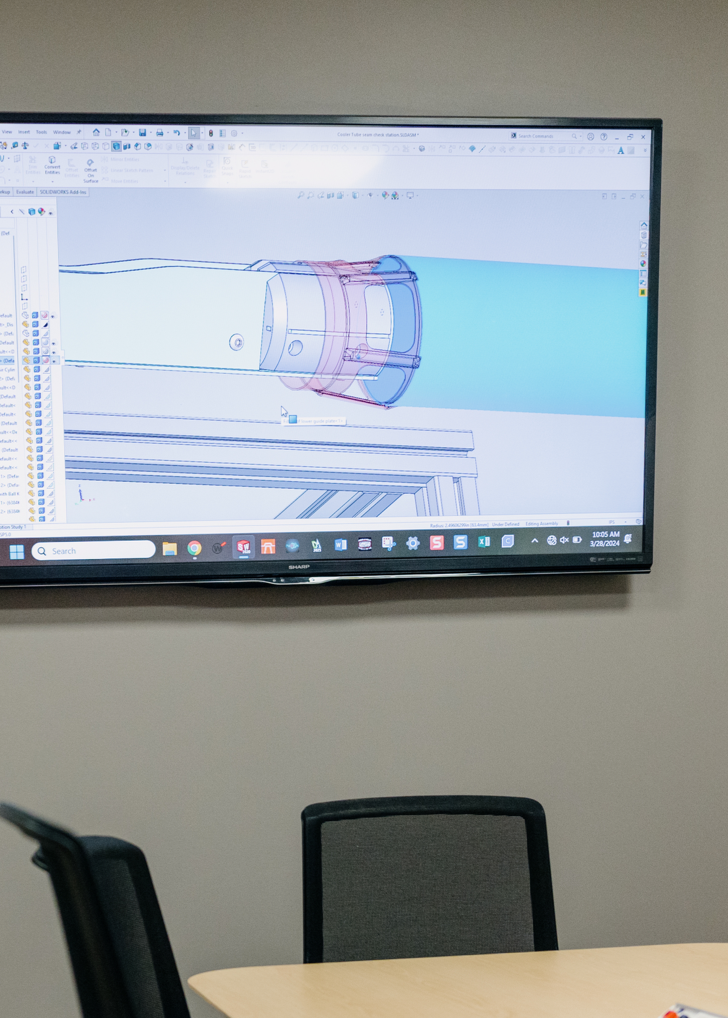

- Prototyping: Our in-house prototyping and R&D facilities allow us to quickly develop and validate new product designs, helping our customers stay ahead of the competition.

- Tooling: MES designs and builds custom tooling solutions, including progressive, line, and transfer dies, to support high-volume production and ensure optimal performance.

Partner with MES for Automotive Excellence

Choosing MES means partnering with a company dedicated to innovation, quality, and customer satisfaction. Our comprehensive automotive solutions and commitment to excellence ensure that we deliver the best possible results for our clients. Contact us today to learn more about our automotive capabilities and how we can support your projects.

Automotive

Shift Tube

Car console shifter tubes have traditionally been manufactured from machined tubing. Middleville Engineered Solutions reviewed this part and recognized an opportunity to improve an existing manufacturing process while reducing costs. MES developed a proprietary method that transformed the formerly machined parts into metal stampings. This stamped design has many benefits, including significant cost savings.

Automotive

Headrest Tube

This part has traditionally been manufactured by welding a tube to a fine blanked stamping. After welding, the part had to go through several secondary operations to add additional features and requalify the part for dimensional accuracy. MES developed a proprietary method that transformed this part into a one-piece design made from Ultra High Strength Steel (UHSS). This one-piece design has many benefits, including significant cost savings.